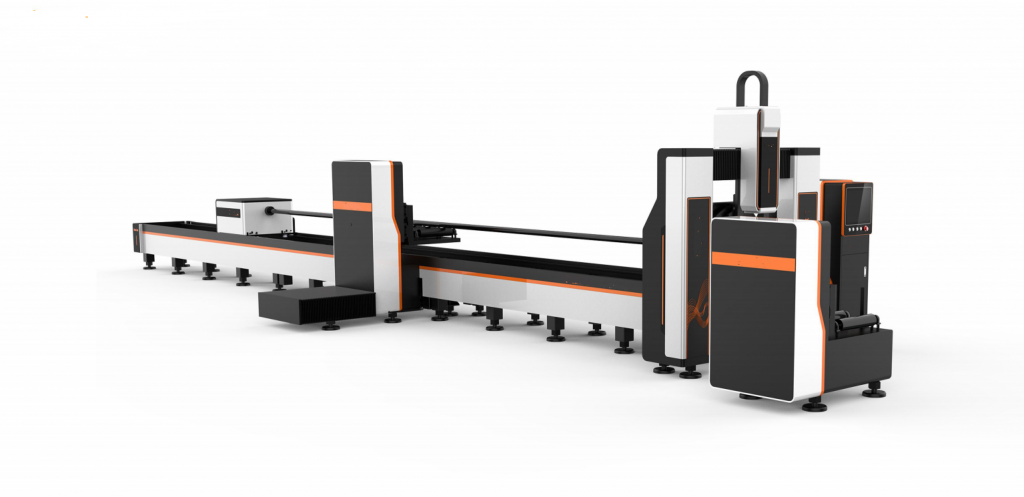

500mm tube laser cutting machine client test

LT Tube laser cutting machine is hot in these month, CNC tube laser cutting machine will be better than plasma cutting machine in drilling marking and the precision.

advise all clients can test the machine before order,advise all clients can test the machine before order, it is necessary for you to keep the business safe and confirm your decision is correct.

Some videos of Client's on-site inspection

H beam cnc tube laser cutting test

Tube cnc tube laser cutting test

Laser cutting channel steel profile has many advantages, let us introduce them one by one:

High precision: laser cutting technology uses a high energy density laser beam for cutting, which has very high positioning accuracy and cutting precision. This enables the cut channel steel sections to meet very precise size and shape requirements, reducing the need for secondary processing.

High quality cutting surface: The laser cutting process has no direct contact with the surface of the workpiece, so it does not lead to problems such as mechanical deformation, cutting defects or cutting burrs. The cutting surface is smooth and neat, reducing the need for subsequent processing.

Flexibility: laser cutting is suitable for a variety of different materials and thicknesses of channel steel profiles. Whether it is ordinary carbon steel, stainless steel, aluminum alloy or other special alloy steel, laser cutting can be competent, and at the same time, it is suitable for different thicknesses of steel profiles.

Automation and digitalization: laser cutting equipment can be connected to computer control systems to realize digital operation and automated production. This helps to increase productivity, reduce manual labor, and ensure product consistency and stability.

Minimal heat-affected zone: The heat-affected zone during laser cutting is small and does not cause deformation or deterioration of the material. As a result, laser cutting is ideal for applications with stringent material requirements, such as in the aerospace and automotive industries.

Material saving: laser cutting is computer-controlled, which allows for optimized scheduling, minimizing material waste and reducing production costs.

Fast cutting speed: laser cutting has a relatively fast cutting speed, which can significantly improve productivity, especially in mass production and batch processing.

Overall, the advantages of laser cutting channel steel profiles are high precision, quality cutting surface, flexibility, automation and digitalization, minimum heat affected zone, material saving and fast cutting speed. These advantages make laser cutting one of the important material processing methods in modern industrial production.