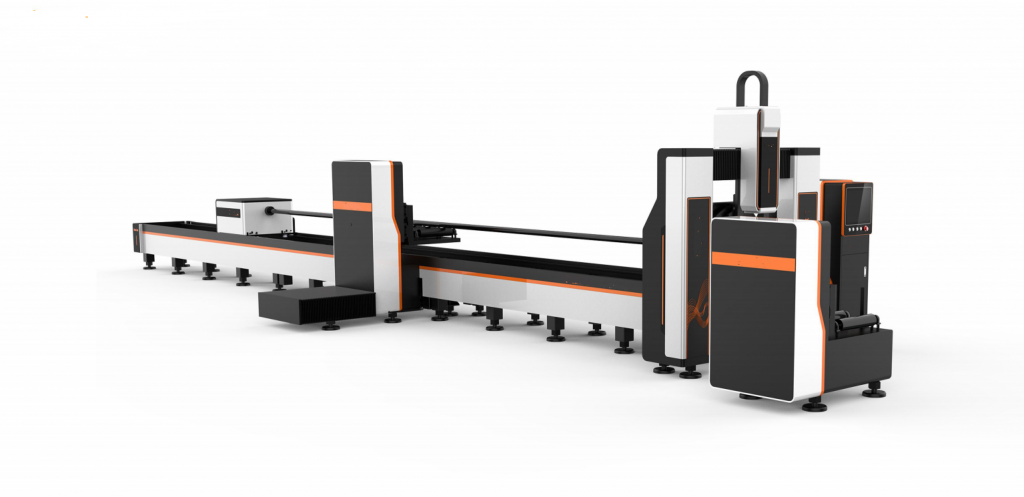

Cnc H Beam Cutting robot plasma cutter Line

We have three H beam cutter lines that can cut H beam. one is 8 axis cnc plasma cutting machine, H series cutting machine, H beam cutting robot.

8 axis machine adopt the double chuks system, it can cut all kinds of tubes, channels, angles, beams, can bevel.

Our CNC Laser cutting machine can cut H beam too

H Series and robot beam cutting line use the different feeding system from 8 axis plasma cutting machine, it use pushing system, the advantage is fast feeding, fast cutting. but it can not suitable cut round tubes(during cutting round tube, it will shakes)

Beam cutting robot’s advantage is the robt is very stable, and it can cut non-standard beams and tubes.

Beam robot cutter line cutting non-standard shapes

Laser cutting and plasma cutting are two commonly used metal cutting techniques, and both have their own advantages and disadvantages in section steel cutting. The following is a comparison of them in section steel cutting:

Advantages of laser cutting:

High precision: laser cutting uses a high energy density laser beam for cutting, which can realize very high cutting precision and edge quality, and is suitable for the processing of steel profiles with high requirements for cutting precision.

Narrow slit cutting: the laser cutting slit is narrow, usually only a few millimeters wide, which can minimize material waste.

Good weldability: the heat-affected zone of the laser cutting kerf is smaller, resulting in less deformation of the material, so it is easier to achieve high-quality welding in the subsequent welding processing of the laser cut steel section.

Disadvantages of laser cutting:

Relatively slow cutting speed: Compared to plasma cutting, laser cutting has a slower cutting speed, and therefore may be less suitable for high volume steel section cutting requirements.

Limited Cutting Thickness: Laser cutting is suitable for cutting thinner profiles and may require more time and power to complete the cut for thicker profiles.

Advantages of plasma cutting:

High speed cutting: plasma cutting uses a high temperature plasma arc to cut, so the cutting speed is faster and is suitable for beam cutting tasks that require higher cutting speeds.

Ability to cut thicker profiles: Compared with laser cutting, plasma cutting has more advantages in cutting thicker profiles with a wider cutting range.

Wide applicability: plasma cutting can be applied to different types of metal materials cutting, more flexible for the diversified needs of cutting steel profiles.

Disadvantages of plasma cutting:

Slightly lower cutting accuracy than laser cutting: Compared with laser cutting, the cutting accuracy and edge quality of plasma cutting is slightly lower, which is suitable for cutting steel profiles with relatively low precision requirements.

Larger heat-affected zone: the heat-affected zone of plasma cutting is larger than that of laser cutting, which may lead to larger thermal deformation around the cut opening of the steel section.

To summarize, the choice of laser or plasma cutting in profile cutting depends on the specific needs. If the cutting accuracy requirements are higher, and the cutting material is thinner, laser cutting is a better choice; if you need to cut thicker profiles at high speed, and the accuracy requirements are relatively low, plasma cutting is more suitable.