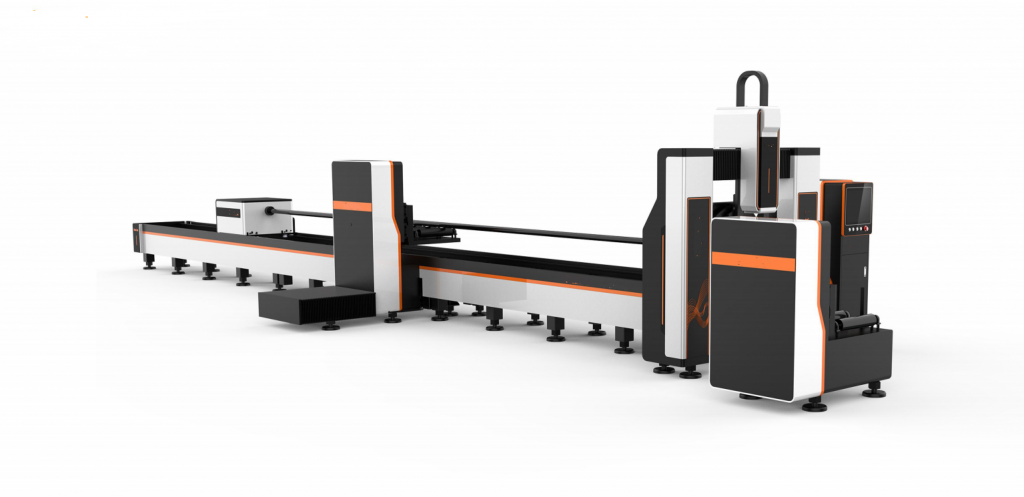

metal manufacturing machines

This steel fabrication pipe machine is special CNC equipment which is used for steel fabrication automatically.It can realize auto program and auto CNC nesting work for any complicated joint type of intertube,pipe,etc. and can cut any type welding bevelling intersection one-time.

Industry :this metal manufacturing machines widely used for steel structure,shipbuilding, oil and gas, bridge and heavy machine industries.

The roll bed plasma cutting machine is well-suited for cutting big pipes

A “roll bed” plasma cutting machine is a type of CNC plasma cutting machine equipped with a rotating bed or chuck that can hold and rotate large pipes during the cutting process. This type of machine is specifically designed for cutting big pipes, tubes, and cylindrical objects. The rotating bed allows the pipe to be rotated, while the plasma cutting torch remains stationary, enabling precise and consistent cutting around the circumference of the pipe.

1:Accurate and Consistent Cuts: The rotating bed ensures that the pipe is positioned accurately, resulting in consistent cuts along the entire length of the pipe.

2:Efficient and Productive: By allowing continuous cutting without the need to reposition the pipe manually, the roll bed machine improves productivity and reduces downtime.

3:Versatility: The machine can handle pipes of various diameters and lengths, making it suitable for cutting a wide range of pipe sizes.

4:Automation and CNC Control: The machine is typically CNC-controlled, allowing for the creation of complex cutting patterns and shapes, making it suitable for various industries and applications.

5:Clean Cuts: Plasma cutting provides clean, precise cuts on a variety of metals, including carbon steel, stainless steel, and aluminum, commonly used in pipe manufacturing.

6:Reduces Manual Labor: Using a roll bed plasma cutting machine reduces the need for manual labor to handle and reposition large pipes, minimizing operator fatigue and potential errors.

When selecting a roll bed plasma cutting machine for cutting big pipes, it’s essential to consider factors such as the maximum pipe diameter and length the machine can accommodate, cutting speed, plasma power source, and the availability of additional features like bevel cutting capability.

It’s worth noting that while the roll bed plasma cutting machine is suitable for big pipes, other cutting methods like laser cutting or waterjet cutting may also be viable options depending on the specific requirements and material properties of the pipes being processed. Consulting with a metal fabrication expert or a reputable machine supplier can help you determine the most appropriate cutting solution for your specific needs.