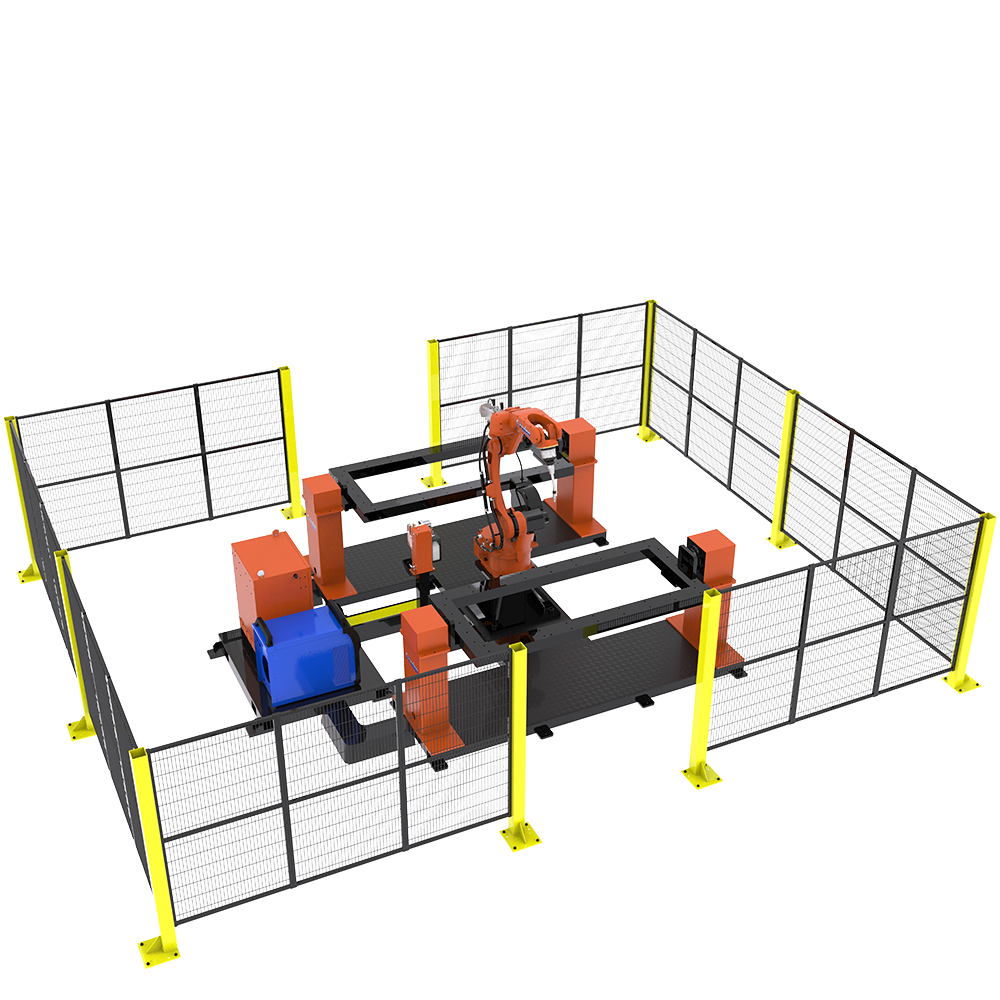

robotic welding machine

A robot welding machine, also known as a robotic welding system, is an advanced industrial automation solution that utilizes robotic technology to perform welding operations. It combines the precision and repeatability of robots with welding capabilities to enhance productivity, quality, and efficiency in welding processes.

Automation control system has the following characteristics:

1. Comes with full keyboard color touch screen keyboard

2.Various application functions such as CO2 gas shielded welding, handling, argon arc welding.

3. Can store 9999 numbers of program (A program can have up to 999 instruction statements)

4. Soft limit protection and alarm function, crash protection (collision pause) function.

5. Code editor,can create, modify and delete any directory to .

6. Robot demonstrator interface is full English, easy to understand, easy to operate. (Support Chinese, English, Japanese interface)

7. Input and output configurable and self-diagnostic functions.

robot welding machines and their advantages:

Robotic Automation: Robot welding machines automate the welding process by utilizing robotic arms equipped with welding torches. These robots can be programmed to perform complex welding tasks with high precision, consistency, and speed. The automation eliminates the need for manual welding, reducing labor costs and improving overall productivity.

Enhanced Weld Quality: Robot welding machines deliver consistent and high-quality welds. The robotic arms execute precise movements and maintain a steady welding speed, resulting in uniform heat distribution and fusion. This leads to improved weld penetration, reduced defects, and enhanced overall weld quality.

Increased Productivity: Robot welding machines significantly increase production rates compared to manual welding. Robots can work continuously without the need for breaks, resulting in higher output and faster project completion. Additionally, they can perform multiple welding operations simultaneously, further improving productivity.

Versatility and Flexibility: Robot welding machines are highly versatile and can handle various welding processes, including arc welding (MIG/MAG, TIG), spot welding, laser welding, and more. They can weld a wide range of materials, including metals such as steel, aluminum, and stainless steel, and adapt to different welding positions and angles. The flexibility of these machines allows for seamless integration into different manufacturing environments and welding applications.

Improved Safety: Robot welding machines improve workplace safety by reducing the exposure of human operators to hazardous welding conditions. Welding robots can handle the welding process in hazardous environments, including those with high temperatures, toxic fumes, or tight spaces. This minimizes the risks associated with manual welding, creating a safer work environment for human workers.

Precise Welding Path Control: Robot welding machines utilize advanced programming and motion control systems to execute precise welding paths. The welding parameters, such as torch angle, arc length, and travel speed, can be precisely controlled and adjusted to meet specific welding requirements. This level of control ensures accurate weld placement and minimizes material waste.

Data Monitoring and Analysis: Many robot welding machines come equipped with advanced software and sensors that allow for real-time data monitoring and analysis. This capability enables manufacturers to track welding performance, monitor key parameters (e.g., weld quality, cycle times), and make data-driven decisions for process optimization and quality improvement.

Scalability and Adaptability: Robot welding systems can be easily scaled or reprogrammed to accommodate changing production needs or welding requirements. They can be integrated into existing production lines or configured for standalone operations. This scalability and adaptability make robot welding machines a valuable long-term investment for manufacturers.

robot welding machines offer numerous advantages, including increased productivity, improved weld quality, enhanced workplace safety, and the ability to handle a wide range of welding processes and materials. By harnessing the power of automation and robotic technology, these machines drive efficiency, cost-effectiveness, and competitiveness in the welding industry.