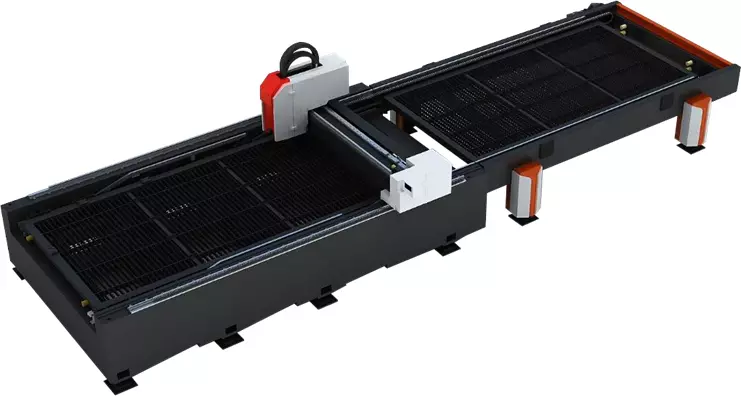

12kw cnc fiber laser cutting machine

Laser cutting works by directing a high-powered laser beam onto the material, which then vaporizes or melts the material, leaving a precise and clean cut. The higher the power of the laser, the faster it can cut through the material.

A 12kW laser cutter can handle thicker and denser materials compared to lower power laser cutters. However, it may also require more energy and may have higher maintenance and operating costs.

Some common applications for a 12kW laser cutting machine include industrial manufacturing, aerospace, automotive, and construction industries, where precision and efficiency are crucial.

However, it is important to note that a 12 kW laser cutting machine requires proper safety precautions, as the high-powered laser beam can be dangerous if not handled correctly. It is important to have proper training and safety measures in place before operating such equipment.

12kw cnc fiber laser machine is a good tool for metal cutting

12000W cutting carbon steel thickness: 1-50mm;

cutting stainless steel thickness: 1-45mm;

aluminum alloy: 1-45mm;

brass: 1-20mm

Laser cutting is a non-contact cutting method. The cutting principle is to heat the channel steel material to a molten or evaporated state by means of a high-energy-density laser beam, and then use a gas stream to blow the molten material away from the cutting gap. Since laser cutting involves no actual physical contact, there are no cutting tools and no tool wear or chipping. This makes laser cutting of channel steel a slag-free cutting method that avoids the hassle of subsequent processing.

Since laser cutting does not introduce tool vibration or cutting forces, it produces a very smooth cutting surface. The cut surface is usually free of burrs, spurs or rough surfaces, which makes the cut edges of the channel very flat and neat.