how the laser cut square tube steel

Laser cutting of square tubes is a highly precise and efficient process that involves using a high-powered laser beam to melt or vaporize the material along a specific path, guided by a computer-controlled system. The laser beam is typically focused to a very small point, providing high energy density that can quickly and accurately cut through the material.

To cut a square tube with a laser, the tube is first secured in the machine’s holding fixture or chuck. The laser cutting machine is then programmed with the desired cutting path, and the machine’s laser head moves along the tube’s length, following the programmed path to create the desired cut.

The laser beam heats the material along the cutting path, causing it to melt or vaporize, and a high-pressure gas, usually nitrogen or oxygen, is simultaneously blown through the cutting nozzle to remove the molten or vaporized material from the cutting zone. The result is a precise, clean, and accurate cut that follows the programmed path.

Laser cutting of square tubes can be used to create a wide variety of shapes and designs, and it is a popular method for producing parts and components for a variety of industries, including aerospace, automotive, and construction, among others.

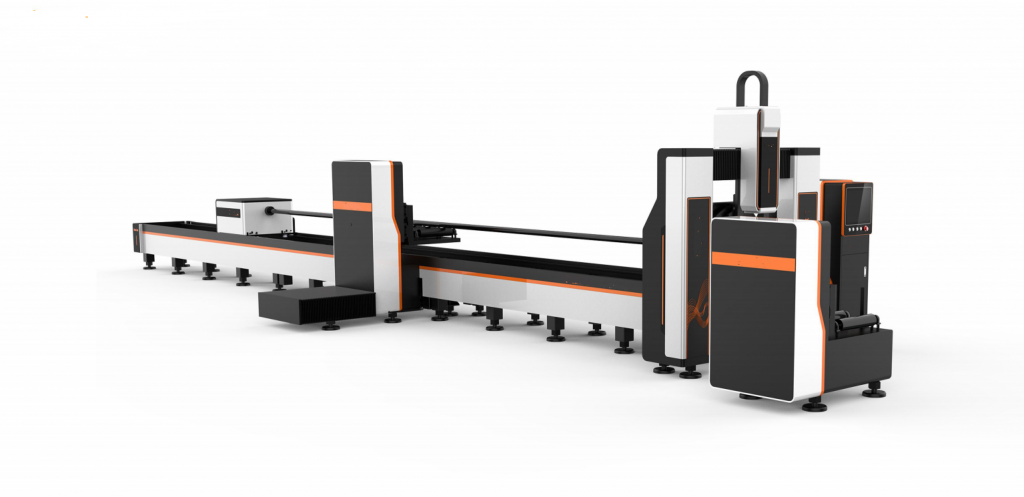

machine that cut square tube

Consistent Performance: Count on our Profile Cutting Production Line to deliver consistent and reliable performance, day after day. Its robust construction and intelligent automation guarantee minimal downtime and optimized production cycles.

Safety and Efficiency: Safety is paramount. Our Profile Cutting Production Line is equipped with advanced safety features, ensuring a secure working environment for your operators. Additionally, its energy-efficient design minimizes power consumption, contributing to sustainability.