how to use laser cutting machine cut i beam

Using a laser cutting machine to cut an I-beam is a complex process that requires careful preparation and operation. Here are the general steps to follow:

Prepare the I-beam: Make sure the I-beam is clean and free from any debris, rust, or other contaminants that could interfere with the cutting process. Secure the I-beam to the laser cutting machine using clamps or other suitable methods to prevent it from moving during cutting.

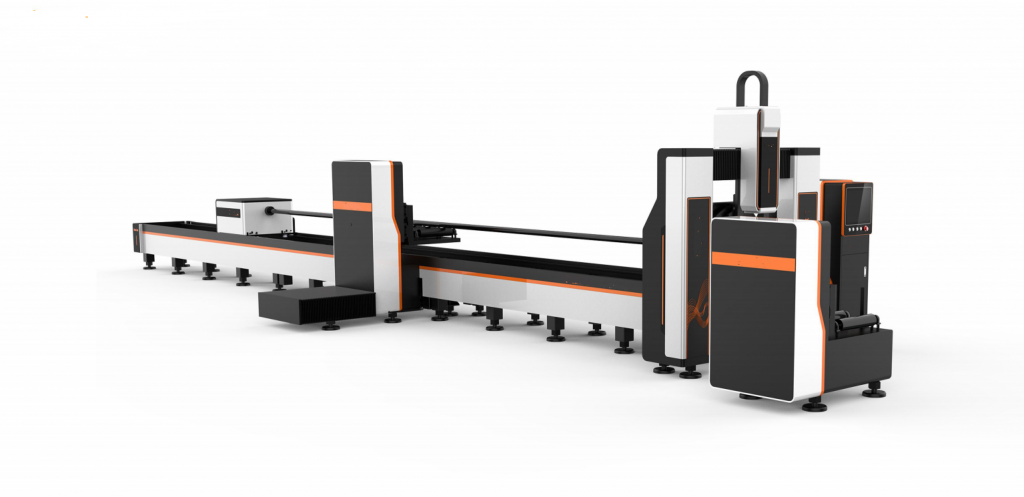

Select the appropriate laser cutting machine: Choose a laser cutting machine that is capable of cutting through the thickness of the I-beam. The machine should also have a large enough bed size to accommodate the I-beam.

Set up the laser cutting machine: Adjust the machine’s settings to match the thickness and material of the I-beam. This includes setting the laser power, cutting speed, and gas pressure.

Load the I-beam onto the machine: Use the clamps or other securing methods to load the I-beam onto the machine’s bed. Make sure it is properly aligned and positioned.

Start the cutting process: Turn on the laser cutting machine and begin the cutting process. Monitor the cutting progress and adjust the settings as needed to ensure a clean and precise cut.

Remove the I-beam: Once the cutting process is complete, remove the I-beam from the machine and inspect the cut for any defects or imperfections.

It’s important to note that cutting an I-beam with a laser cutting machine can be dangerous if proper safety precautions are not taken. Be sure to follow all safety guidelines and wear appropriate personal protective equipment.

Advantage of laser cutting machine in I beam cutting

Laser cutting machines offer several advantages when it comes to cutting I-beams:

Precision: Laser cutting machines are capable of producing highly precise cuts with minimal distortion, even on complex shapes and designs. This precision ensures a high-quality finished product and reduces the need for additional machining or finishing.

Speed: Laser cutting machines are much faster than traditional cutting methods, such as sawing or plasma cutting. This allows for quicker turnaround times and increased productivity.

Versatility: Laser cutting machines are highly versatile and can be used to cut a wide range of materials, including steel, aluminum, and other metals. This makes them ideal for cutting I-beams of different materials and sizes.

Clean cuts: Laser cutting produces very clean, precise cuts with minimal burrs, resulting in a high-quality finished product. This eliminates the need for additional finishing processes and reduces material waste.

Automation: Laser cutting machines can be automated, allowing for consistent, repeatable cuts without the need for manual labor. This saves time and reduces the risk of human error.

Overall, the advantages of laser cutting machines in I-beam cutting make them a popular choice for many industrial applications.