One cut all machine choose

Carbon steel structural beams are manufactured in two configurations. Both are constructed with a vertical web in the center of the beam, with horizontal flanges on top and bottom. The structure of the beam provides superior load-bearing support.

CNC 8 axis plamsa cutting machine is an all-in-one machine that can profile beams, angle bar, channel, square tubes, and now pipes, plates, T-bars and bulbs! This high-performance plasma cutting machine for H beam coping has unmatched accuracy and is equipped with Perfect Hole technology.

cnc plasma air machine in steel structure

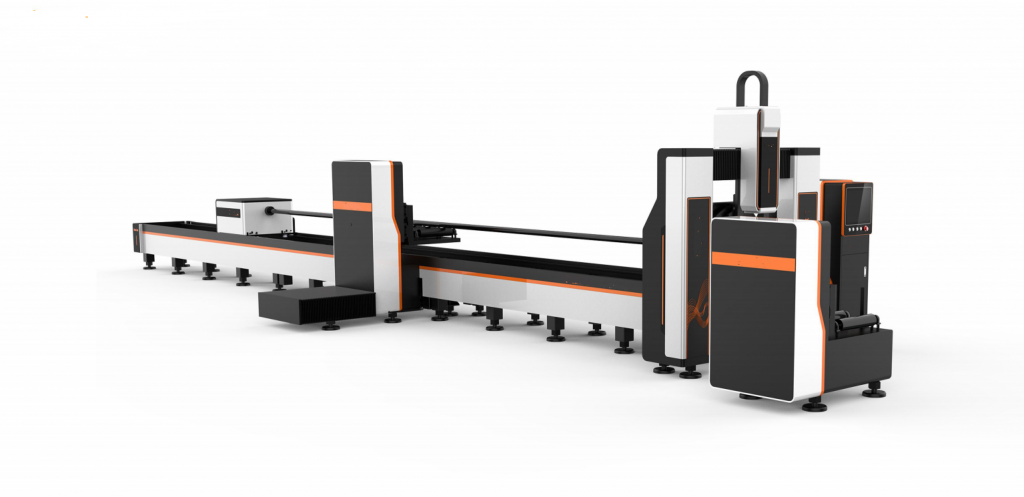

But if you want a better cutting works, you need choose laser cutting machine, laser cutting machine is ALL-IN-ONE machine too, it’s cuting arrange will be larger than plasma cutting machine, beside the square/rectangle/round tube, it can cut oval tubes, and others

cnc laser machine in steel structure

What is the difference between plasma and laser cutting machine?

Laser cutting machines and plasma cutting machines are two different tools used to cut materials, and they have some significant differences in cutting accuracy, cutting thickness, cutting speed, cutting section and secondary processing of the cut workpiece.

Cutting Accuracy: Laser Cutting Machines

Laser Cutting Machines: A laser cutting machine has a very high degree of precision, allowing for very detailed and complex cuts. This makes it suitable for applications where precision is critical, such as miniature parts or cutting tasks that require a high degree of geometric accuracy.

Plasma Cutting Machines: Plasma cutting machines typically cut with less precision than laser cutting machines, especially when working with complex or detailed designs.

Cutting Thickness: Laser Cutting Machines

Laser Cutting Machines: For thin to medium thickness materials, laser cutting machines are very effective. However, for materials thicker than a certain limit, a higher power laser source may be required.

Plasma Cutters: Plasma cutters are more effective when working with materials thicker than 0.5 inches (12 mm).

Cutting Speeds: Laser Cutting Machines: For thin materials, plasma cutters are more effective.

Laser Cutting Machines: For thin materials and complex designs, laser cutting is generally faster than plasma cutting.

Plasma Cutting Machines: Plasma cutting is generally faster when working with thick materials.

Cutting Sections: Laser Cutting Machines

Laser Cutting Machines: Laser cutting machines produce a very smooth cut section and usually do not require additional post-processing.

Plasma Cutting Machines: Plasma cutting machines have a rougher cut section and usually require subsequent polishing or finishing.

Secondary processing of the cut part.

LASER CUTTING MACHINES: Due to their high precision and smooth cut sections, no additional secondary processing is usually required.

Plasma Cutting Machines: Due to their relatively low accuracy and rough cut sections, additional polishing, trimming, or other secondary processes may be required