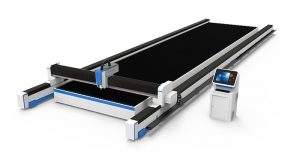

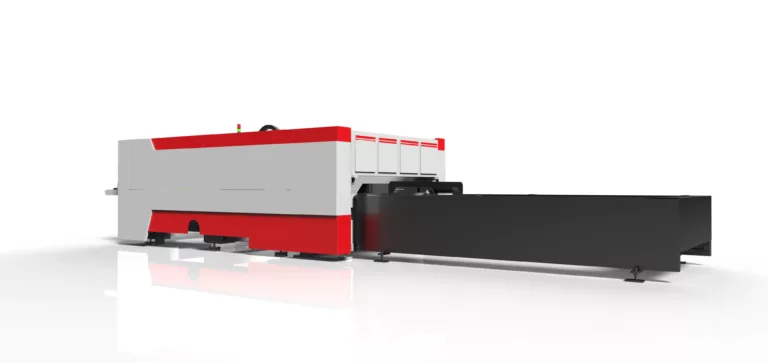

Automatic H Beam Steel Cutting Machine

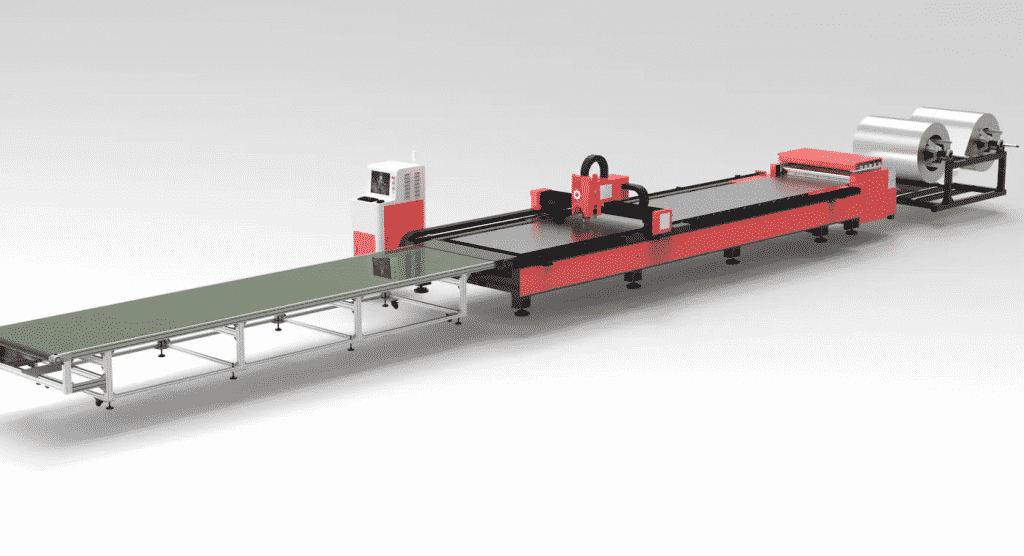

The automatic H beam steel cutting machine is a type of industrial machine used to cut H-shaped steel beams automatically. It is designed to improve efficiency and accuracy in steel fabrication and manufacturing processes.

The machine consists of a cutting head, which can move along multiple axes, and a computer control system that provides instructions for the cutting process. The H-shaped steel beams are loaded onto the machine and secured in place before the cutting process begins.

The cutting process can be done using a variety of methods, including plasma cutting, flame cutting, and saw cutting. The machine can be programmed to make precise cuts with minimal waste, which can help reduce costs and improve productivity. These tools use high temperatures to melt or burn through the steel, creating a clean, precise cut.

Automatic H beam steel cutting machines are commonly used in the construction industry for fabricating steel structures, such as buildings, bridges, and tunnels. They can also be used in the manufacturing of heavy machinery, such as cranes and excavators.

Overall, the use of an automatic H beam steel cutting machine can help companies save time and money while increasing production efficiency and accuracy.

why choose the plasma cutting machine to cut H beam steel

CNC plasma cutting machines are an excellent choice for cutting H beams due to several reasons:

Speed and Efficiency: CNC plasma cutting machines are fast and efficient, which is ideal for cutting H beams with high precision and speed. They can cut through a variety of materials, including steel, aluminum, and other metals, with ease.

High Precision: CNC plasma cutting machines offer high precision and accuracy, which is important when cutting H beams that are required to fit together perfectly. This results in fewer errors and reduces the amount of rework required.

Versatility: CNC plasma cutting machines can be used to cut a variety of shapes and sizes, including H beams. They can be programmed to cut custom shapes and sizes, which is ideal for creating unique designs.

Cost-Effective: CNC plasma cutting machines are a cost-effective solution for cutting H beams, as they can operate continuously without the need for manual intervention. This reduces labor costs and increases production efficiency.

Automated Operation: CNC plasma cutting machines are designed for automated operation, which means that they require minimal operator intervention. This reduces the risk of errors and increases safety in the workplace.

Overall, CNC plasma cutting machines are an excellent choice for cutting H beams due to their speed, precision, versatility, cost-effectiveness, and automated operation.